SONIMA is always at your disposal on site, at your customer’s or at your supplier’s. We work reliably and flexibly in equal measure and act in a customer-oriented manner. This ensures a continuous demand supply of inspected parts without influencing the production process. To safeguard your processes, we support you from incoming goods through the firewall to outgoing goods.

- Ensuring the continuous flow of parts 24/7

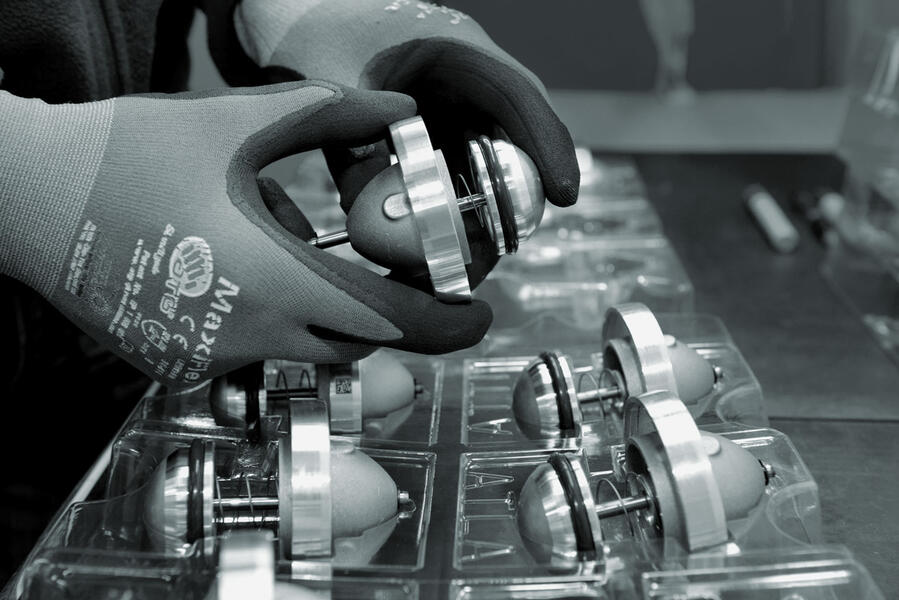

- Sorting and reworking as well as checking the goods internally and externally

- Development of checklists as well as work and test instructions

- Visualisation of the test characteristics

- Process safeguarding

Your products are sorted, checked and reworked according to your requirements.

In addition, we offer you the option of working with your employees to develop checklists, work and inspection instructions and documentation for future error prevention. The evaluation of the checked quantity and defect images will be made available to you promptly in the desired form. In addition to pure sorting analyses, directly processed data, such as Pareto analyses, can also be produced. Afterwards, we are happy to support you in defining and implementing measures that serve to prevent errors in the long term.